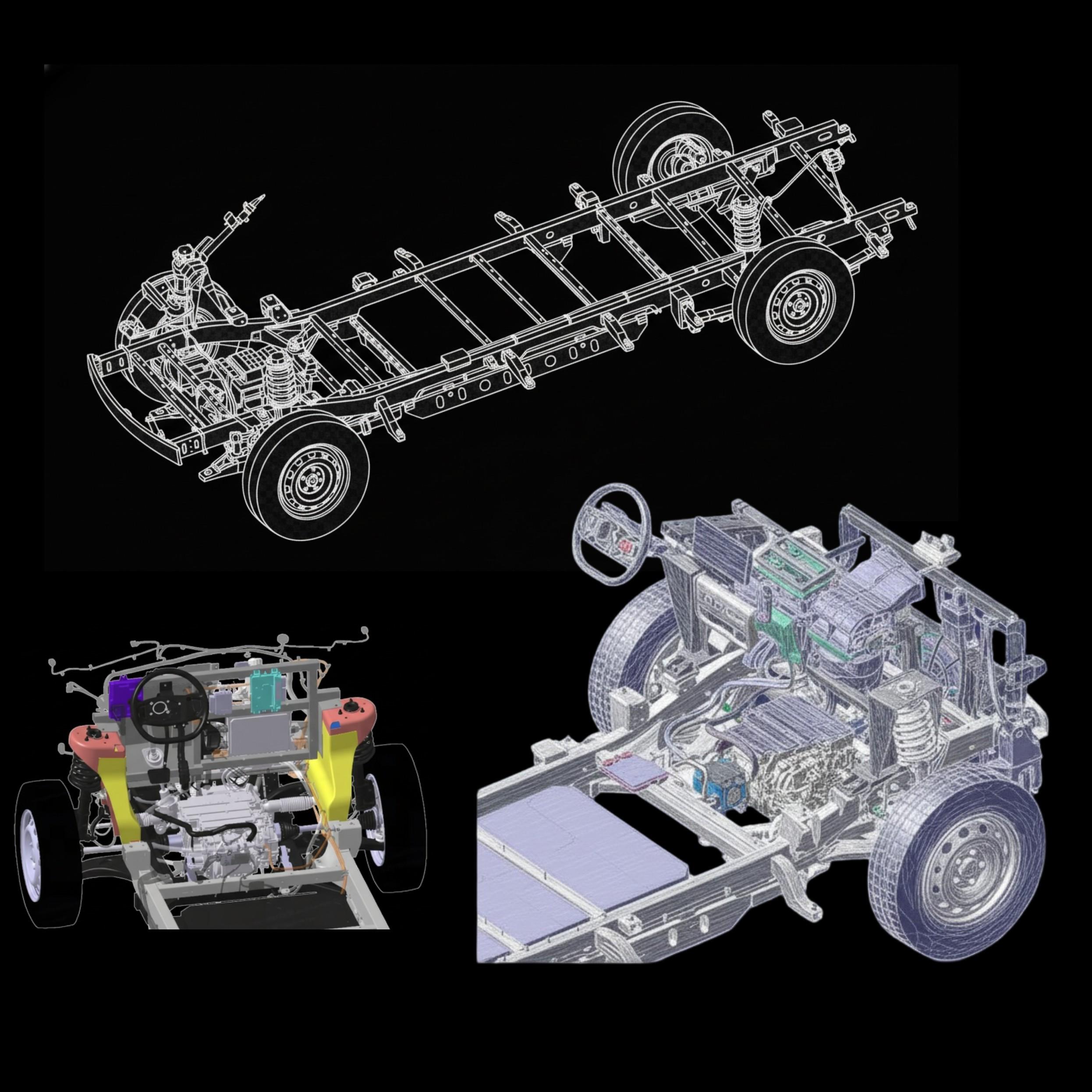

Electric Chassis:

How Modern EVs Are Built

Why electric chassis design is fundamentally different from gas cars—and why it matters.

An electric chassis isn't just a gas chassis with batteries. It's a complete rethink of how vehicles are built.

Skateboard Architecture

Called "skateboard" because that's what it looks like—flat battery deck with wheels at the corners. Batteries in the floor. Motors at the axles. Everything as low as possible.

Traditional cars stack components vertically: engine, transmission, driveshaft, differential. This raises the center of gravity and wastes interior space. Electric skateboards distribute weight horizontally across the floor.

Why It Works Better

Lower center of gravity: Battery weight sits inches off the ground. Less body roll in corners. Can use softer suspension for comfort without sacrificing handling.

Better weight distribution: Spread batteries across the whole floor for near-perfect 50/50 balance. Gas cars with front engines are 60/40 at best.

Flat floor: No transmission tunnel or driveshaft eating interior space. Walk-through cabins in vans become possible.

Battery Integration

The battery pack is structural—not cargo sitting in a box. The aluminum enclosure carries loads and adds rigidity to the chassis. This saves weight by eliminating redundant structure.

What's Inside

Thousands of individual lithium-ion cells grouped into modules. Each module has cooling channels and temperature sensors. Battery Management System monitors every module for voltage, temperature, and health.

Thermal Management

Liquid cooling keeps batteries in the 20-40°C sweet spot. Too hot degrades life. Too cold kills range. Coolant circulates through the pack, then flows to radiators up front.

In winter, the system reverses—uses motor waste heat to warm the battery before fast charging.

Motor and Drivetrain

Olympus uses a single rear motor: 174 HP continuous, 200+ HP peak. Permanent magnet motor for efficiency. Single-speed reduction gear—no transmission needed because electric motors deliver full torque from zero RPM.

No clutch, no shift solenoids, no torque converter. Just bearings and gears. 200,000+ mile service life.

Drive-by-Wire Controls

No mechanical linkages. Steering wheel inputs are electronic signals to actuators. Brake pedal is digital. This enables features impossible with cables and hydraulics:

- Adjustable steering weight via software

- One-pedal driving with aggressive regen

- Remote operation for autonomous applications

Olympus Specs

- Battery: 42-54 kWh structural pack

- Motor: 130 kW PMSM (174 HP)

- Voltage: 400V nominal

- Range: 155-255 miles

- Wheelbase: 183-196" adjustable

- Payload: 3,550 lbs above chassis weight

- Charging: DC fast + Level 2 AC

Why Modular Matters

One chassis platform, multiple body types. Change wheelbase, swap body tooling, manufacture entirely different vehicles. This enables low-volume production economically.

Developing a new EV from scratch: $500M-$2B and 4-5 years. Using a pre-engineered chassis: 60-80% cost reduction and 12-18 months to production.

Bottom Line

Electric chassis architecture returns automotive manufacturing to its roots—specialized chassis builders make platforms, body designers make vehicles. This separation enables faster development, lower costs, and more diversity.

The Olympus Electric Chassis is available now. Pre-certified, tested, ready to build on.

Build on the Olympus Electric Chassis

The platform is ready. Configure your chassis and start building.

Configure Your Chassis