Reinventing automotive

manufacturing In United States

Olympian Motors is at the forefront of the rapidly growing electric vehicle market.

We are reinventing car manufacturing by bringing agility, speed and cost-efficiency to the American automotive industry.

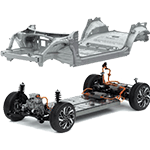

We developed a new Modular Vehicle and Drivetrain System (MVDS) with 4 core hardware modules and 2 software/OS modules. Our innovative MVDS approach resembles a 'Lego' architecture. That provides strong cost and lead-time advantages in manufacturing operations, and allows Olympian to bring top-quality electric vehicles to market more quickly.

Olympian Impact

- We achieved an 80 % reduction in tooling, machinery, fitment & labor costs.

- We accomplished 60 % faster production lead time compared to legacy automakers in the United States.

- Our design - to - production period from is 8 months compared to a 6+ year average in the US.

- Introduced a robust, innovative, modular manufacturing and supply - chain model that removes bureaucracy, middle - managers, bottlenecks and superfluous powerpoint files.

Manufacturing

Olympian Motors is reinventing automotive manufacturing in the United States.

Our innovative modular system, 'MVDS', provides significant cost and lead-time advantages, allowing us to bring high-quality electric vehicles to market safely and rapidly. We minimized traditional tooling and machinery expenses, reduced production lead times and built a robust, Lego-like production and supply-chain model.

We bring speed, cost-efficiency and agility back to the industry.

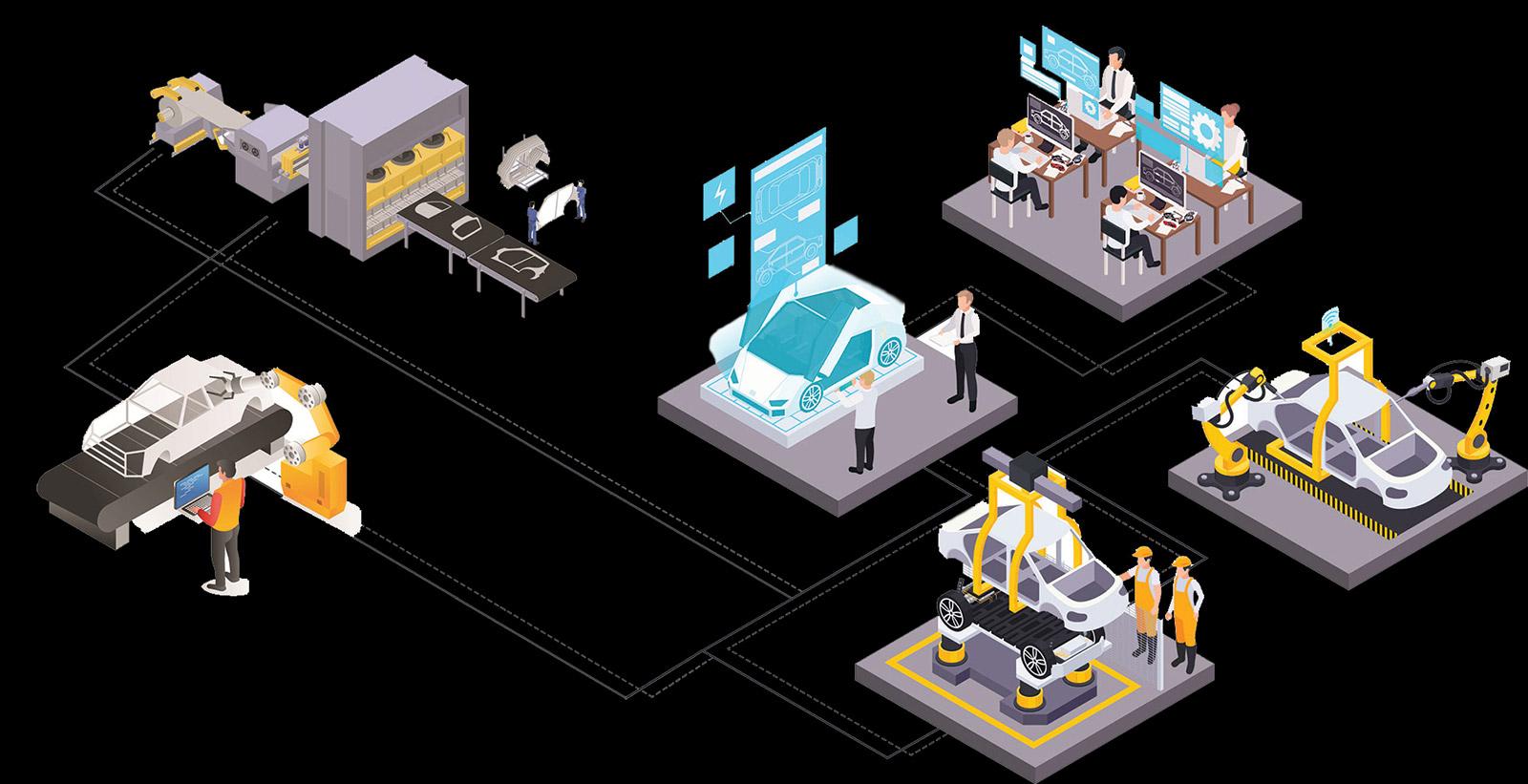

Modular EV Production Model

Built on the Olympian MVDS platform, our team operates a decentralized production model across adaptive tooling, robotic welding, CNC, 3D printing, wiring harness, low voltage, module calibration, testing and final assembly.

Our objective is to manufacture highly modular EVs with low inventory, low CAPEX, and a highly automated production model.

Our Bases

Brooklyn Navy Yard, New York

- Test-drives, prototyping, tooling, CNC, Metal/Wood Processing, 3D Printing, painting, final assembly and infotainment software/OS module development.

- Technology & IP development partnerships with mobility and engineering companies in the Navy Yard

Michigan Central, Detroit (Q4/2023)

- Cross-collaboration with Tier-1 and Tier-2 ODMs, contract manufacturers, component suppliers, quality control, testing and engineering partners.

Steel.

Wood.

Fire.

Drive steel, touch wood, feel tactile.

We prioritized using steel, wood, natural fibers, and recycled materials in Olympian vehicles.

Our Key Principles

Our main objective is to manufacture highly modular electric vehicles with a low inventory, low CAPEX, lean organization and a highly automated production model.

Modular vehicle and

drivetrain architecture

Low Inventory

➜ Low Working Capital

Smart Tooling

➜ Minimized Capex

Lean and Robust

Organization

Robust manufacturing and supply chain

Olympian introduced a robust, innovative, modular manufacturing and supply-chain model to the industry.

Our innovative MVDS approach resembles a 'Lego' architecture. That provides strong cost and lead-time advantages in manufacturing operation.

100% Modular / Lego Architecture

>80% reduction in tooling costs

>50% faster production lead-times

<100 days order-to-delivery time